Deep groove ball bearing is the most common type of rolling bearing.

Deep groove ball bearing

The basic deep groove ball bearing is composed of an outer ring, an inner ring, a group of steel balls and a group of retaining structures. There are two types of deep groove ball bearings: single row and double row. The deep groove ball structure is also divided into sealed and open structures. Open means that the bearing does not have a sealed structure. The sealed deep groove ball is divided into dust seal and oil seal. The material of dust-proof sealing cover is steel plate stamping, which only plays a simple role in preventing dust from entering the bearing raceway. The oil proof type is a contact oil seal, which can effectively prevent the overflow of lubricating grease in the bearing.

The type code of single row deep groove ball bearing is 6. It has simple structure and convenient use. It is the most common and widely used type of bearing in production.

working principle

Deep groove ball bearings mainly bear radial load, and can also bear radial load and axial load at the same time. When it only bears radial load, the contact angle is zero. When the deep groove ball bearing has large radial clearance, it has the performance of angular contact bearing and can bear large axial load. The friction coefficient of deep groove ball bearing is very small and the limit speed is also very high.

Bearing characteristics

Deep groove ball bearing is the most commonly used rolling bearing. The utility model has the advantages of simple structure and convenient use. It is mainly used to bear radial load, but when the radial clearance of the bearing is increased, it has certain performance of angular contact ball bearing and can bear combined radial and axial load. When the rotating speed is high and the thrust ball bearing is not suitable, it can also be used to bear pure axial load. Compared with other types of bearings with the same specification and size of deep groove ball bearing, this kind of bearing has small friction coefficient and high limit speed. But it is not resistant to impact and is not suitable to bear heavy load.

After the deep groove ball bearing is installed on the shaft, the axial displacement in both directions of the shaft or shell can be limited within the axial clearance of the bearing, so it can be positioned axially in both directions. In addition, this kind of bearing also has a certain centering ability. When it is inclined by 2 ′~ 10 ′ relative to the shell hole, it can still work normally, but it has a certain impact on the service life of the bearing.

Structure and classification

Bearing structure

Deep groove ball bearing has simple structure and is easy to achieve high manufacturing accuracy compared with other types, so it is convenient for series mass production, low manufacturing cost and widespread use. In addition to the basic type, the deep groove ball bearing also has various variant structures, such as: deep groove ball bearing with dust cover, deep groove ball bearing with rubber sealing ring, deep groove ball bearing with stop groove, deep groove ball bearing with large load capacity with ball notch, and double row deep groove ball bearing.

Bearing type

Deep groove ball bearing is mainly used to bear radial load, but it is also commonly used to bear radial and axial composite load. Especially when the rotating speed of mechanical equipment is very high and it is not suitable to use thrust bearing, the bearing can be used to bear two-way pure axial load without maintenance during operation. It is a kind of bearing with low price and wide application. Deep groove ball bearing models include: deep groove ball bearing (60000 type); Deep groove ball bearing with stop groove on the outer ring (60000n type); Deep groove ball bearing with dust cover on one side and stop groove on the outer ring on the other side (60000-zn type); Deep groove ball bearing with dust cover on both sides and stop groove on the outer ring (60000-2zn type); Deep groove ball bearing with dust cover on one side (60000z type); Deep groove ball bearing with dust cover on both sides (60000-2z type); Deep groove ball bearing with sealing ring on one side (60000-ls type and 60000-rz type); Deep groove ball bearings with sealing rings on both sides (60000-2ls and 60000-2rz); Flange outer ring deep groove ball bearing (f60000 type); Flange outer ring deep groove ball bearing with dust cover on one side (f60000-z type); There are 11 kinds of flange outer ring deep groove ball bearings with dust cover on both sides (f60000-2z type).

According to the size of deep groove ball bearing, it can be divided into:

(1) Miniature bearing -- bearing with nominal outer diameter less than 26mm;

(2) Small bearings -- bearings with nominal outer diameter ranging from 28 to 55mm;

(3) Small and medium-sized bearings -- bearings with nominal outer diameter ranging from 60 to 115mm;

(4) Medium and large bearings -- bearings with nominal outer diameter ranging from 120 to 190mm

(5) Large bearing -- bearing with nominal outer diameter ranging from 200 to 430mm;

(6) Extra large bearing ---- bearing with nominal outer diameter of more than 440mm.

Processing form

The processing forms of deep groove ball bearing parts are as follows:

1. Multi process processing: general bearing production requires 20 ~ 40 processes, with more than 70 processes.

2. Forming processing: the working surfaces of bearing parts are rotary forming surfaces, which are suitable for processing by forming method.

3. Precision machining: most surfaces of bearing parts need to be ground, and the grinding dimension and geometric accuracy are based on μ M is single

Installation method

Installation method 1 of deep groove ball bearing: press fit: when the inner ring of the bearing fits tightly with the shaft and the outer ring fits loosely with the bearing seat hole, the bearing can be pressed on the shaft with a press, and then the shaft and the bearing are installed into the bearing seat hole together. During press fit, an assembly sleeve (copper or mild steel) made of soft metal material is padded on the end face of the bearing inner ring, When the outer ring of the bearing fits tightly with the bearing seat hole and the inner ring fits loosely with the shaft, the bearing can be pressed into the bearing seat hole first. At this time, the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the seat hole If the bearing ring is tightly matched with the shaft and seat hole, the inner ring and outer ring in the installation chamber shall be pressed into the shaft and seat hole at the same time, and the structure of the assembly sleeve shall be able to press the end faces of the bearing inner ring and outer ring at the same time.

Installation method 2 of deep groove ball bearing: heating fit: the installation method of changing tight fit into loose fit by heating bearing or bearing seat and using thermal expansion It is a common and labor - saving installation method This method is suitable for the installation of bearings with large interference. Before hot installation, put the bearing or the ferrule of separable bearing into the oil tank and heat it evenly for 80-100 ℃, then take it out of the oil and install it on the shaft as soon as possible. In order to prevent the end face of inner ring and shaft shoulder from not fitting tightly after cooling, the bearing can be tightened axially after cooling When the outer ring of the bearing is tightly matched with the bearing seat made of light metal, the hot installation method of heating the bearing seat can avoid scratching the mating surface. When heating the bearing with the oil tank, there should be a mesh grid at a certain distance from the bottom of the box, or the bearing should be hung with a hook. The bearing should not be placed on the bottom of the box to prevent sinking impurities from entering the bearing or uneven heating. There must be a thermometer in the oil tank, and the oil temperature must be strictly controlled not to exceed 100 ℃ to prevent tempering effect and reduce the hardness of the ferrule.

tolerance

The standard deep groove ball bearing has ordinary grade, which is all in line with GB / T 307.3-1996.

Clearance

The radial clearance of bearing is divided into original clearance, installation clearance and working clearance. Usually, the original radial clearance of the bearing is greater than the clearance when the bearing is working. Clearance is an important technical parameter of bearing. It directly affects the technical performance of bearing, such as load distribution, vibration, noise, friction, service life and mechanical motion accuracy. Strictly speaking, the rated dynamic load of the bearing changes with the size of the clearance. The rated load (C and C0) listed in the product sample is the load value when the working clearance is zero. If the clearance is too large, it will reduce the bearing area inside the bearing, increase the stress of the rolling contact surface, reduce the motion accuracy of the bearing, increase the vibration and noise, and shorten the service life of the bearing: if the clearance is too small, it will cause heating and temperature rise, and even lead to the phenomenon of "seizure" of the bearing during operation. Therefore, it is very important to select different levels of bearing clearance according to the type of bearing and working conditions.

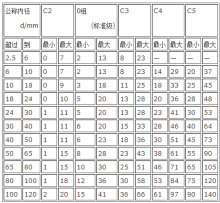

Standard deep groove ball bearings have internal clearances of C2, CN, C3, C4 and C5, which are all in line with gb4604· The radial clearance of deep groove ball bearing is shown in the table below.

Cage

Deep groove ball bearings generally use steel plate stamping cage or brass solid cage. When the outer diameter is less than 400mm, the steel plate stamping cage is adopted without post code. When the outer diameter is greater than 400mm, the brass solid cage is mostly used without post code.

matters needing attention

The bearing load of deep groove ball bearing is too small during operation, which will cause sliding between the ball and the raceway and become the cause of scratch. In particular, large deep groove ball bearings with heavy ball and cage have this tendency. In many cases, the bearing will be rusted. There are many reasons for bearing corrosion. The most common factors in our daily life are the following:

1) Due to poor sealing device, it is invaded by moisture and dirt;

2) The bearing is not used for a long time, which exceeds the rust prevention period and lacks maintenance.

3) The metal surface roughness is large;

4) Contact with corrosive chemical media, the bearing is not cleaned cleanly, there is dirt on the surface, or contact the bearing with sweaty hands. After cleaning, the bearing is not packaged or installed in time, and is exposed to the air for a long time, which is invaded and contaminated by air moisture;

5) Ambient temperature and humidity and exposure to various environmental media; The antirust agent is invalid or the quality does not meet the requirements.